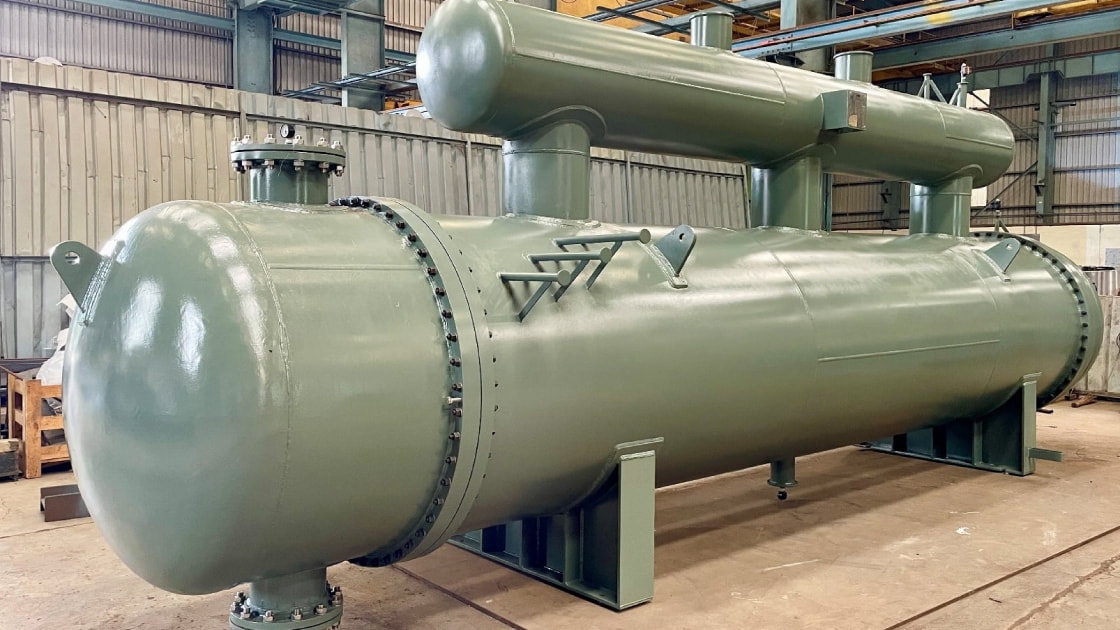

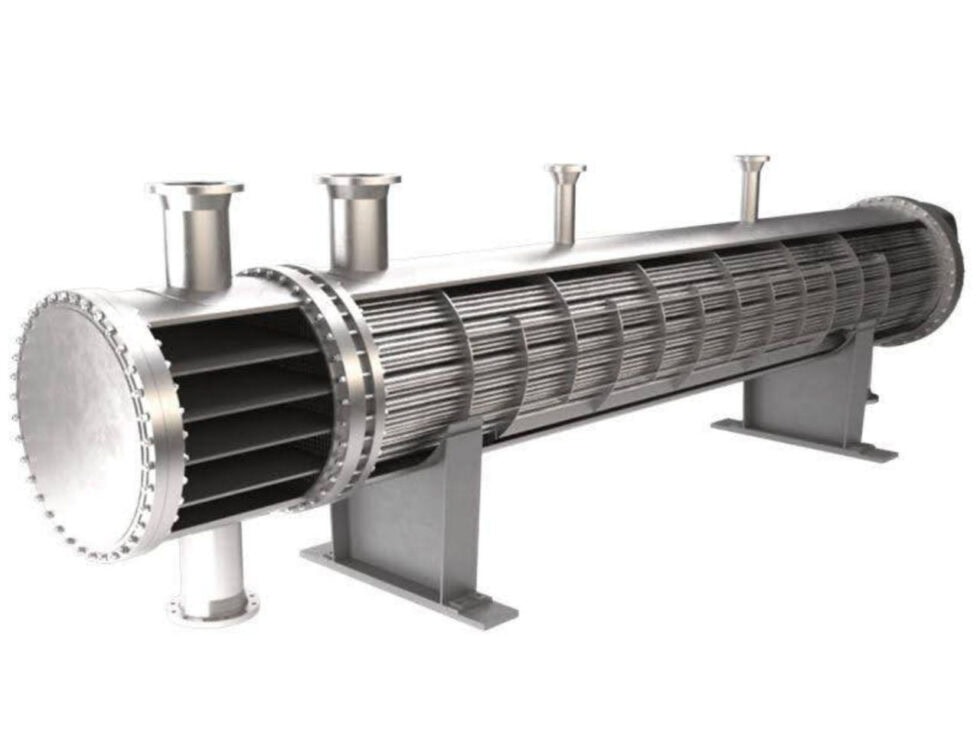

Heat exchangers are critical components in numerous industrial systems and HVAC applications, ensuring efficient thermal transfer between fluids. Over time, however, they can accumulate debris, mineral scale, biological fouling, or chemical deposits, leading to reduced performance, increased energy costs, and potential mechanical failures.

Cleaning your heat exchanger not only restores efficiency but also prolongs the lifespan of the equipment. This guide provides an in-depth look into why cleaning is essential, how to identify when cleaning is necessary, and the methods and precautions involved.

Signs Your Heat Exchanger Needs Cleaning

Recognizing early indicators of fouling or blockages can prevent costly downtime and damage. Common signs include:

- Reduced thermal performance: Noticeable drop in heat transfer efficiency, often reflected in system output temperatures.

- Increased pressure drop: Higher differential pressure readings across the heat exchanger indicate flow restrictions caused by deposits.

- Rising energy consumption: Pumps and fans may consume more power to maintain target performance due to reduced flow or heat exchange capacity.

- Visible scaling or fouling: External inspections may reveal deposit buildup on accessible surfaces.

- Unusual noises or vibrations: Loose debris or corrosion can cause changes in flow dynamics.

Safety Precautions Before You Begin

Cleaning a heat exchanger involves mechanical, chemical, and potentially high-pressure processes that require adherence to strict safety protocols. Always:

- Isolate and depressurize the heat exchanger from the system before starting maintenance.

- Wear appropriate PPE including gloves, goggles, and protective clothing to safeguard against chemical exposure and sharp edges.

- Follow lockout/tagout procedures to prevent accidental activation of pumps, fans, or other system components.

- Use proper ventilation when working with chemical cleaning agents to avoid inhalation hazards.

- Consult and comply with industry standards such as ASME Section VIII for pressure equipment and the manufacturer’s recommended procedures.

Tools and Materials You’ll Need

Preparing the right equipment in advance will make the cleaning process safer and more effective.

- Basic hand tools: wrenches, screwdrivers, torque tools for disassembly and reassembly.

- Soft and stiff brushes for mechanical cleaning.

- High-pressure water jet or steam cleaning system.

- Approved chemical cleaning solutions (e.g., descalers, degreasers) compatible with heat exchanger metallurgy.

- Collection trays or drip pans to capture debris and rinse water.

- Inspection tools: borescopes, calipers, and gauges to check cleaning effectiveness.

Methods of Cleaning

The most appropriate cleaning method depends on the exchanger type (shell-and-tube, plate, air-cooled) and the nature of the deposits.

Mechanical Cleaning

Mechanical cleaning is ideal for stubborn deposits such as thick scale, biological fouling, or solidified debris. This may involve:

- Rod and brush cleaning: Inserting rods with cleaning brushes or scrapers into tubes to physically remove deposits.

- High-pressure water jetting: Using directed jets to flush away loose contaminants without damaging tube walls.

- Steam cleaning: Effective for grease or oil residues, especially in food processing or petrochemical applications.

Care must be taken to avoid surface damage, particularly to thin-walled tubes or plates.

Chemical Cleaning

Chemical cleaning is best for mineral scaling, chemical deposits, or biological growth that mechanical means cannot fully remove. The process typically involves:

- Circulating an acid-based descaler (for minerals) or alkaline cleaner (for organic deposits) through the exchanger.

- Monitoring pH and temperature to ensure safe and effective dissolution.

- Neutralizing and flushing the system post-cleaning to prevent corrosion or residue.

Always ensure chemical compatibility with exchanger materials (e.g., stainless steel, titanium, copper alloys) to prevent corrosion or pitting. API and manufacturer guidelines should be consulted for concentration limits and circulation times.

Other Methods

- Backflushing: Reversing fluid flow to dislodge debris caught in narrow passages.

- Ultrasonic cleaning: Employing high-frequency sound waves in a fluid bath to break apart deposits.

- Dry ice blasting: Non-abrasive particle blasting suitable for sensitive surfaces.

These methods may be combined with mechanical or chemical processes for comprehensive cleaning.

Steps for Reassembly and Final Inspection

- Ensure all cleaning residue, chemicals, and water are fully drained from the exchanger.

- Conduct a visual inspection using borescopes or high-intensity lighting to verify cleanliness.

- Replace any worn gaskets, seals, or O-rings before reassembly.

- Tighten bolts to the manufacturer’s specified torque to avoid leaks and ensure structural integrity.

- Perform a hydrostatic pressure test to confirm no leaks before returning to service.

- Document the cleaning process, findings, and operational checks for future maintenance reference.

Common Mistakes to Avoid

- Using incompatible chemicals: This can cause corrosion or damage gasket materials.

- Skipping neutralization: Residual cleaning agents can lead to long-term degradation.

- Excessive mechanical force: Aggressive brushing or scraping can erode protective films or cause through-wall damage.

- Ignoring manufacturer guidelines: Deviations may void warranties or reduce service life.

- Incomplete rinsing: Remaining cleaning agents can react with process fluids in harmful ways.

Preventive Maintenance Tips

Consistent maintenance reduces buildup and extends operational efficiency:

- Implement scheduled inspections based on process fluid type and operating conditions.

- Install filtration systems upstream to minimize particulate ingress.

- Control fluid chemistry and temperature within recommended ranges to reduce scaling potential.

- Monitor performance metrics such as temperature differential and pressure drop to catch fouling early.

- Maintain logs of cleaning cycles, inspection reports, and component replacements for trend analysis.

Conclusion

Cleaning your heat exchanger is an essential part of maintaining system efficiency, safety, and longevity. By understanding the signs of fouling, using appropriate cleaning methods, and following strict safety protocols, you can avoid costly breakdowns and ensure optimal thermal performance. Preventive maintenance is equally important, allowing you to minimize fouling and extend the time between cleanings.

For specialized cleaning services or complex industrial heat exchanger maintenance, trust experienced professionals who understand the intricacies of mechanical and chemical cleaning compliant with industry standards. Contact our expert team today to discuss tailored solutions for your application and keep your heat exchangers performing at peak efficiency.