Heat exchangers are at the heart of countless industrial, commercial, and even residential systems. Their ability to efficiently transfer thermal energy between two or more fluids makes them vital in processes such as chemical manufacturing, oil refining, power generation, and HVAC systems. Without properly designed and maintained heat exchangers, energy consumption rises, productivity drops, and equipment can suffer premature wear.

Whether you are an engineer specifying equipment for a new plant, a facility manager looking to reduce energy costs, or a technical buyer evaluating suppliers, understanding the fundamentals of heat exchangers is essential. This guide walks through what they are, how they work, where they are used, and how to choose and maintain them effectively.

What is a Heat Exchanger?

A heat exchanger is a device that transfers heat between two or more fluids liquids, gases, or a combination without mixing them directly. The fluids are separated by solid boundaries, such as tube walls or plates, enabling thermal energy to pass while maintaining fluid integrity. Heat exchangers are categorized by their construction, flow arrangement, and application.

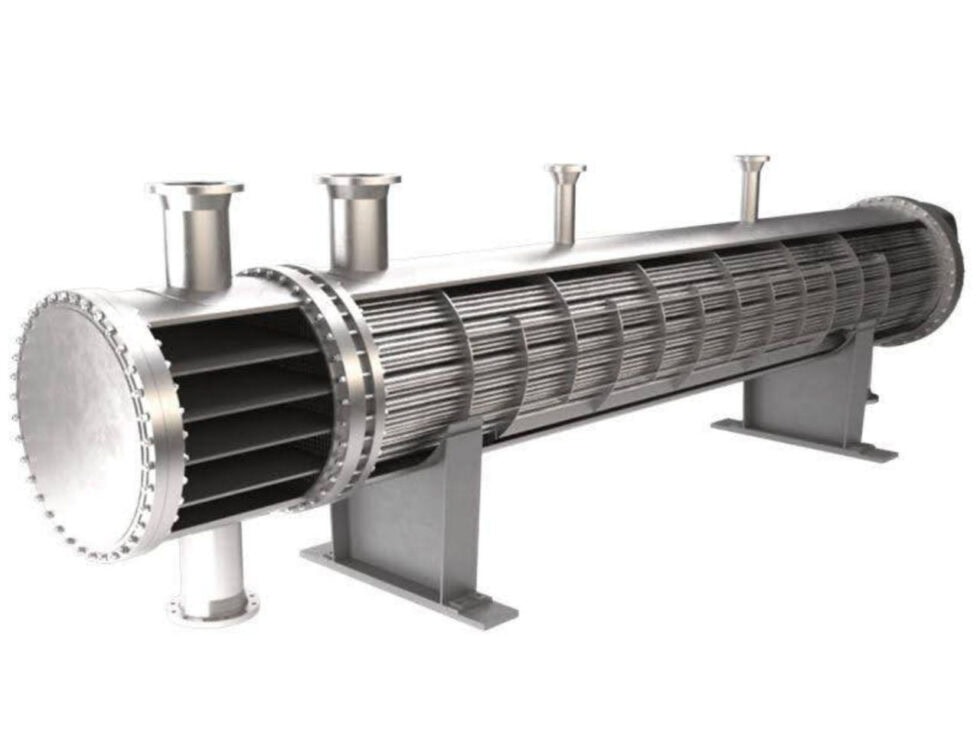

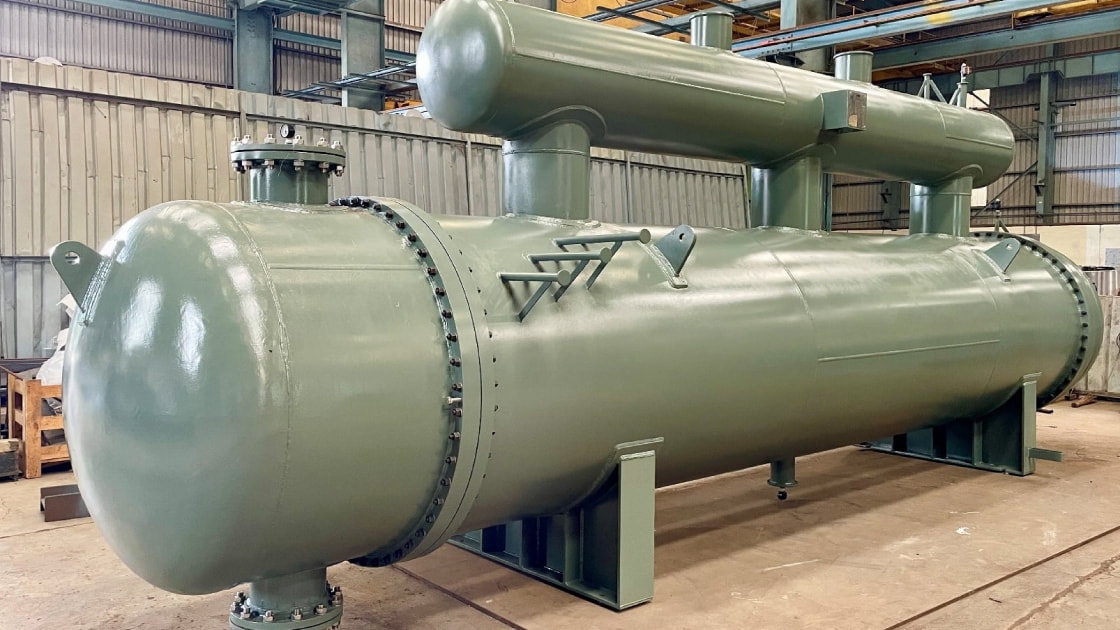

- Shell and Tube Heat Exchangers: Composed of a shell housing bundles of tubes; one fluid flows through the tubes while the other surrounds them.

- Plate Heat Exchangers: Utilize corrugated plates stacked together; high efficiency in compact applications.

- Air-Cooled Heat Exchangers: Use ambient air to cool process fluids, ideal in areas where water is scarce.

- Double Pipe Heat Exchangers: Simple coaxial pipe arrangement; often used for smaller thermal duties.

Industry standards such as TEMA (Tubular Exchanger Manufacturers Association) and ASME codes ensure these units meet strict design and safety requirements.

How a Heat Exchanger Works

The operation of a heat exchanger is governed by the principles of thermodynamics, specifically conduction and convection. Heat flows from the hot fluid to the cold fluid through a separating wall, driven by the temperature difference and thermal conductivity of the wall material.

Step-by-Step Operation:

- Step 1: Fluid Entry – Hot and cold fluids enter the exchanger through designated inlet nozzles or ports.

- Step 2: Flow Arrangement – Common configurations include counterflow, parallel flow, and crossflow. Counterflow generally offers superior thermal efficiency.

- Step 3: Heat Transfer – As the fluids move, heat passes across the boundary wall. The rate of transfer depends on factors like surface area, flow velocity, and the overall heat-transfer coefficient (U-value).

- Step 4: Fluid Exit – Cooled hot fluid and warmed cold fluid exit via outlet ports.

Heat Transfer Equation: Q = U × A × ΔTlm

Where:

- Q = Heat transfer rate (W)

- U = Overall heat-transfer coefficient (W/m²·K)

- A = Heat transfer surface area (m²)

- ΔTlm = Log mean temperature difference (K)

Common Applications in Various Industries

Heat exchangers are ubiquitous in modern industry. Some key application sectors include:

- Oil & Gas: Crude oil preheating, gas dehydration, and refinery distillation units.

- Chemical Processing: Reactant heating and cooling, condensation, solvent recovery.

- Power Generation: Steam condensers, turbine lubrication cooling, waste heat recovery boilers.

- HVAC Systems: Chilled water coils, refrigerant condensers, district heating supply.

- Food & Beverage: Pasteurization, sterilization, packaging line temperature control.

- Mining: Slurry cooling, smelter off-gas energy recovery.

- Desalination Plants: Brine coolers, feedwater preheaters.

Advantages and Limitations

Advantages:

- Efficient energy use and recovery, lowering operational costs.

- Customizable designs for specific thermal tasks.

- Broad range of materials available, providing corrosion resistance and durability.

- Compact models available for space-constrained facilities.

Limitations:

- Sensitivity to fouling, which can lower heat transfer efficiency.

- Potential for thermal stress and cyclic fatigue in extreme temperature swings.

- Initial capital cost for specialized materials or high-pressure designs.

- Pressure drop limitations may require design compromises to maintain flow rates.

Balancing these factors involves considering lifecycle cost, maintainability, and compliance with standards such as API 661 for air-cooled exchangers or ASME Section VIII for pressure vessels.

How to Choose the Right Heat Exchanger

Selecting an appropriate heat exchanger involves both thermal design and mechanical integrity considerations:

- Gather Operational Data – Flow rates, inlet/outlet temperatures, allowable pressure drop, fluid phase and properties.

- Define Thermal Duty – Calculate the required heat load using the heat balance equation.

- Choose Flow Arrangement – Counterflow for maximum efficiency, crossflow if footprint constraints dominate.

- Select Materials – Stainless steel, carbon steel, titanium, or exotic alloys based on corrosion resistance and mechanical properties.

- Check Standards Compliance – Verify that the design meets TEMA, ASME, API, or other industry code requirements.

- Consider Maintenance Accessibility – Removable bundles, cleaning ports, and service clearances reduce downtime.

Software tools like HTRI Xchanger Suite or Aspen EDR can model performance under different conditions, enabling optimized sizing before fabrication.

Maintenance Tips for Longevity

Routine maintenance extends the lifespan and efficiency of a heat exchanger:

- Regular Inspection – Monitor for leaks, corrosion, and scaling.

- Cleaning – Use chemical cleaning, mechanical cleaning, or pigging runs depending on fouling type.

- Monitor Flow Conditions – Avoid low velocity zones that encourage fouling; consider redesign if operating patterns change.

- Check Gaskets and Seals – Replace periodically to prevent leaks.

- Non-Destructive Testing (NDT) – Radiography, ultrasonic thickness checks, and dye penetrant inspections to identify hidden flaws.

A preventive maintenance program compliant with manufacturer recommendations can reduce long-term operating costs significantly.

Conclusion

Heat exchangers are critical components for efficient thermal management in virtually every process industry. They enable energy savings, process stability, and product quality when correctly specified, installed, and maintained. Engineers must weigh design parameters, operating conditions, and economic factors to choose the ideal configuration.

Whether your project involves a compact plate exchanger for a food processing line or a large shell-and-tube unit for petrochemical operations, attention to detail in selection and maintenance translates directly into performance and profitability.

Contact our engineering team today to discuss your heat exchanger needs. From thermal design to on-site servicing, we help you maximize efficiency and extend equipment life — ensuring your facility operates at peak performance.