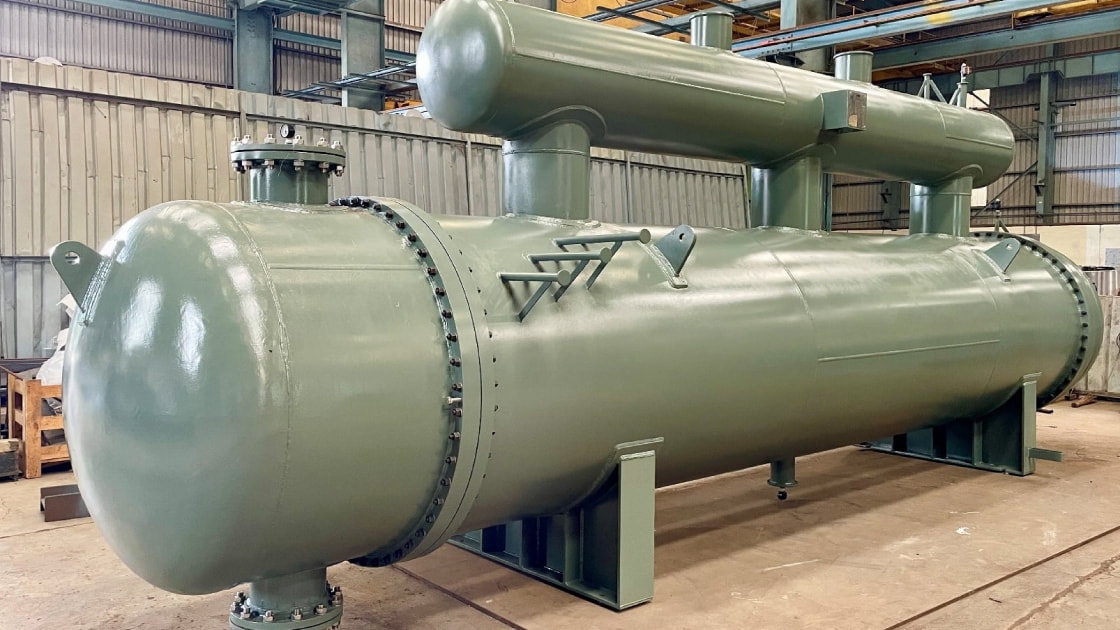

In industrial piping systems whether in oil & gas, petrochemical, power generation, or water treatment precision, reliability, and safety are paramount. One essential component of these systems is the pipe spool.

A pipe spool is a pre-fabricated segment of a piping system, consisting of pipes, fittings, and flanges, assembled into a section that can be transported and installed on-site. Understanding what a pipe spool is, how it is designed, fabricated, and quality-controlled is crucial for ensuring system performance and compliance with industry standards such as ASME B31.3, ASME Section IX, and other applicable codes.

This article will break down the essential aspects of pipe spools: what they are, how they are made, factors influencing their design, standards governing their production, challenges, as well as the industries that depend on them.

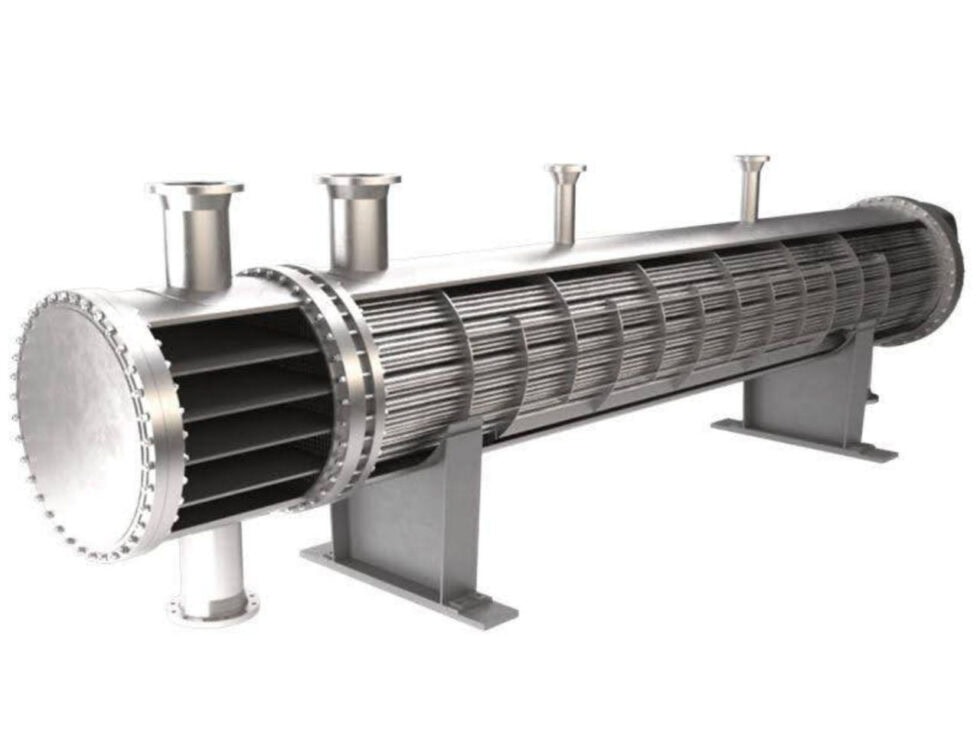

Defining a Pipe Spool

A pipe spool is a piping section built from one or more pipes that are cut, beveled, and joined with fittings (such as elbows, tees, reducers) and flanges to form a modular piece of the overall piping system.

Spools are generally fabricated in a controlled shop environment to meet precise specifications from construction drawings or isometric diagrams. Once complete, the spools are shipped to the installation site, where they are bolted or welded into the existing or new pipeline.

By prefabricating these assemblies, contractors save time in the field and minimize quality risks caused by uncontrolled conditions (weather, limited access, or safety hazards).

Pipe Spool Fabrication Process

The fabrication of pipe spools follows a methodical sequence to ensure compliance with project specifications and industry standards:

Step 1: Review of Drawings and Specifications

Fabricators start by reviewing piping isometrics, general arrangement drawings, and material specifications. These documents indicate dimensions, weld details, flange ratings (e.g., ASME Class 150, 300), and material grades (like ASTM A106 Grade B for carbon steel).

Step 2: Material Procurement

The correct pipe lengths, fittings, and flanges are sourced. Material traceability is critical mill test certificates (MTCs) are maintained for quality assurance.

Step 3: Pipe Cutting and Preparation

Pipes are cut to length using cold cutting machines or oxy-fuel torches, depending on material and thickness. Ends are beveled at specified angles (often 37.5° for weld preparation) to ensure proper weld penetration.

Step 4: Fit-Up and Welding

Pipes and fittings are assembled using alignment jigs. Welding is performed by qualified welders in accordance with approved Welding Procedure Specifications (WPS). Common welding methods include Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), or Flux-Cored Arc Welding (FCAW), depending on material and project requirements.

Each weld must comply with ASME Section IX qualification standards for welders and procedures.

Step 5: Non-Destructive Examination (NDE)

NDE methods such as Radiographic Testing (RT), Ultrasonic Testing (UT), Magnetic Particle Testing (MT), or Dye Penetrant Testing (PT) ensure weld integrity. The level of inspection is determined by project specifications and code requirements.

Step 6: Surface Treatment and Coating

Spools may be blast-cleaned to a specific surface profile before receiving paint or coating systems for corrosion resistance. In corrosive environments, internal linings or cladding may be applied.

Step 7: Hydrostatic Testing

Completed spools can undergo hydro testing, where water is pressurized inside the spool to prove it can withstand its design pressure without leakage or deformation.

Step 8: Identification and Shipping

Spools are tagged with unique identifiers correlating to installation drawings. They are then packed and shipped to site with protective coverings for flanges and ends.

Design Considerations

Several technical factors influence the design of a pipe spool:

- Material Selection: Chosen based on fluid type, temperature, pressure, and corrosion potential. Options include carbon steel, stainless steel, duplex stainless steels, and specialty alloys.

- Pressure Rating: Determined by ASME flange classes and pipe schedule to withstand operational pressures.

- Dimensions and Geometry: Spool length, number of bends, and orientation must fit within the installation envelope and maintain flow efficiency.

- Weld Accessibility: Designs must allow welders access for high-quality welds and subsequent inspection.

- Prefabrication Tolerances: Tolerances set by codes and client requirements ensure proper fit-up in the field.

Standards and Compliance

Fabrication of pipe spools is governed by rigorous standards to ensure safety, reliability, and interchangeability:

- ASME B31.3: Process Piping code outlining design, fabrication, examination, and testing requirements.

- ASME Section IX: Welding qualification requirements for procedures and personnel.

- ASTM Material Standards: Specifications for pipe and fitting materials.

- ISO 9001: Quality management systems for consistent fabrication processes.

Challenges and Limitations

While pipe spool prefabrication offers many benefits, there are considerations:

- Transportation Constraints: Large spools may require special handling or dimensional adjustments for shipping.

- Field Fit Issues: Even with precise fabrication, variations at site (foundation settlement, misaligned supports) can necessitate adjustments.

- Material Availability: Exotic alloys or specialized fittings may have long lead times.

Industries Utilizing Pipe Spools

Pipe spools are critical to many sectors:

- Oil & Gas (upstream, midstream, downstream)

- Petrochemical and chemical processing

- Power generation (fossil fuel and nuclear)

- Pulp and paper manufacturing

- Water and wastewater treatment

- Mining and mineral processing

Benefits of Prefabricated Pipe Spools

Prefabrication delivers measurable advantages:

- Reduced field installation time

- Improved quality control under shop conditions

- Enhanced safety by minimizing hot work on-site

- Lower overall project costs through efficient labor use

- Consistency in fabrication across multiple sections

Conclusion

Pipe spools are integral components in industrial piping systems, combining engineering precision with efficient project execution. By understanding the technical processes behind their fabrication material selection, welding, inspection, and compliance with codes stakeholders can ensure safer, faster, and more cost-effective installations. Companies specializing in pipe spool design and manufacturing bring expertise to navigate these complexities, delivering reliable assemblies tailored to unique operating environments.

For organizations seeking dependable piping solutions, partnering with an experienced fabricator ensures adherence to standards, optimal fit-up on-site, and long-term operational reliability.